Understanding Corrugated Roof Sheets

What Are Corrugated Roof Sheets?

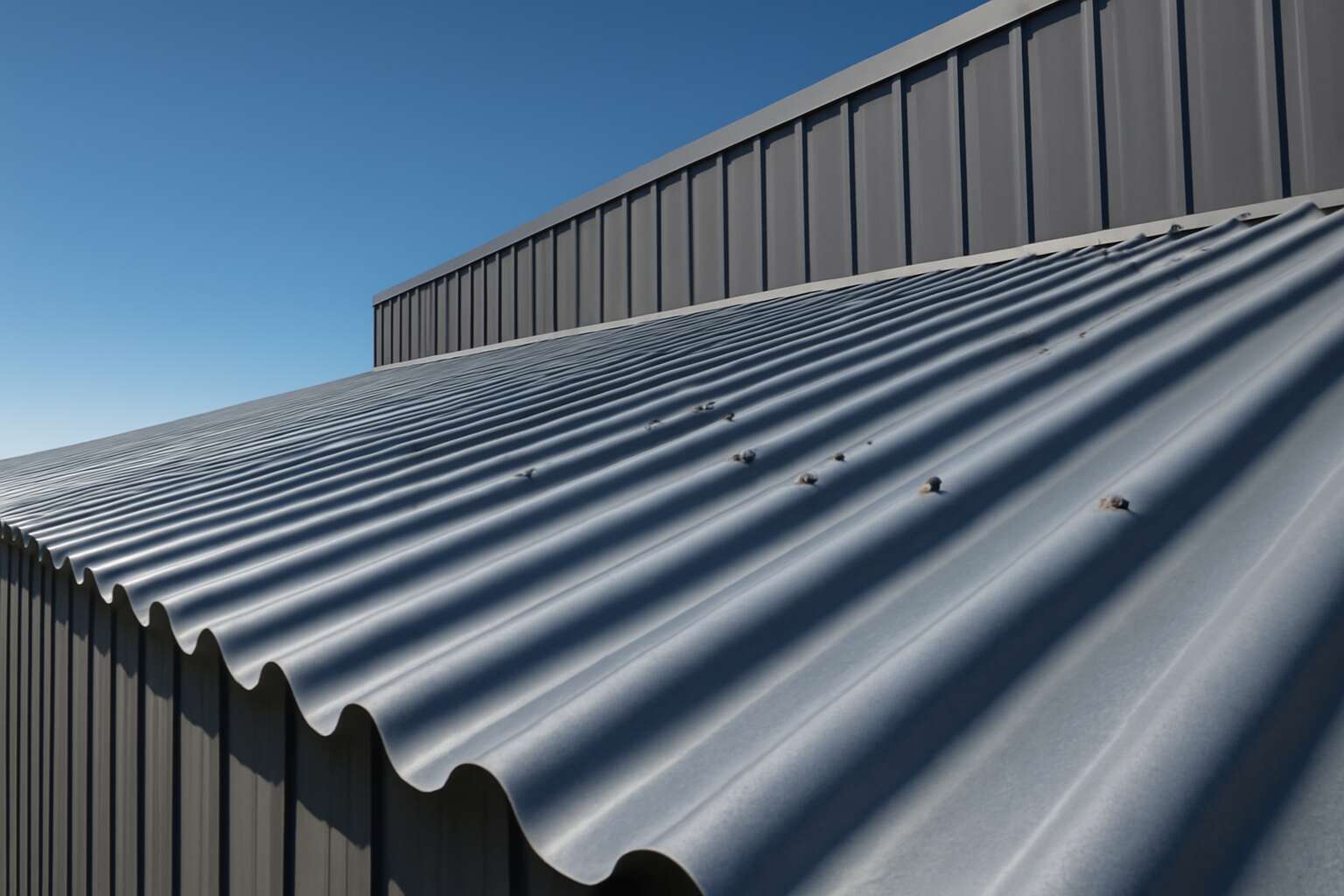

Within the realm of roofing materials, few evoke the same sense of durability and architectural charm as corrugated roof sheets. These resilient panels, often seen majestically arching over warehouses, farm storages, and industrial complexes, possess a storied history that stretches back centuries. Their distinctive rippled pattern isn’t merely aesthetic; it’s a masterstroke of engineering that enhances strength and water runoff. For those seeking the perfect balance of longevity and ease of installation, corrugated roof sheets 3.6m offer an ideal solution—long enough to span wide areas without the need for excessive joints.

What makes corrugated roof sheets truly captivating is their ability to transform a simple structure into a fortress against South Africa’s diverse climate. Their wave-like design distributes stress evenly, providing resilience against wind, rain, and even the occasional hailstorm. When selecting corrugated roof sheets 3.6m, it’s essential to understand the different types available, such as galvanized steel, aluminum, or fiber cement, each bringing its own unique qualities to the table.

- Ease of handling and installation

- Superior water drainage capabilities

- Enhanced structural integrity due to wave pattern

Indeed, corrugated roof sheets have become a symbol of strength and practicality in modern construction—an enduring testament to the ingenuity of traditional craftsmanship infused with contemporary innovation.

Materials Used in Corrugated Roof Sheets

Among the myriad of roofing options, the material composition of corrugated roof sheets 3.6m holds the key to their enduring strength and versatility. Each type of material whispers its own story—whether it’s the shimmering resilience of galvanized steel, the lightweight elegance of aluminum, or the robust, weather-resistant nature of fiber cement. These materials are the backbone of durability, ensuring that each sheet withstands South Africa’s capricious climate with unwavering resolve.

Galvanized steel, often the stalwart choice, is coated in a layer of zinc that acts as a shield against rust and corrosion. Aluminum, on the other hand, offers a feather-light alternative, prized for its corrosion resistance and ease of handling. Fiber cement sheets, with their composite blend, marry strength with fire resistance and minimal maintenance.

- Galvanized steel

- Aluminum

- Fiber cement

Each material contributes to the overall resilience of corrugated roof sheets 3.6m, making them a go-to solution for both industrial and agricultural structures.

Choosing the right material is more than a matter of preference; it’s a strategic decision influenced by the environment and the specific demands placed on a structure. The interplay of these materials creates a symphony of strength, ensuring that corrugated roof sheets 3.6m not only protect but elevate the architectural integrity of any building, standing as a testament to both tradition and innovation.

Advantages of Corrugated Roofing

Corrugated roof sheets 3.6m are more than just a roofing trend—they’re a strategic choice for durability, style, and practicality. Over 70% of industrial and agricultural structures in South Africa rely on these sheets because they blend toughness with affordability. Their wavy profile isn’t just for aesthetic appeal; it’s a clever engineering feat that enhances water runoff, reducing the risk of leaks during the rainy season. Plus, their lightweight nature means quicker installation and less strain on supporting structures—saving time and money.

What truly sets corrugated roof sheets 3.6m apart is their versatility. Whether you’re sheltering crops, equipment, or creating a stylish shed, these sheets adapt seamlessly. They also boast impressive resilience against South Africa’s unpredictable climate, shrugging off heat, rain, and even wind with ease. The added benefit? Low maintenance! A simple clean now and then keeps them looking sharp and functioning perfectly for years to come.

Specifics of 3.6m Corrugated Roof Sheets

Standard Length and Dimensions

The standard length of 3.6m corrugated roof sheets is more than just a measurement; it’s a carefully calibrated dimension that balances ease of installation with structural integrity. In South Africa’s diverse climate, these sheets serve as resilient barriers against both relentless sun and sudden downpours, making their length a crucial factor in ensuring comprehensive coverage. The dimensions of corrugated roof sheets 3.6m are designed to optimize coverage while minimizing waste, allowing for seamless overlaps that enhance durability and weather resistance.

Understanding the specifics of corrugated roof sheets 3.6m involves appreciating how their size influences both aesthetic appeal and functional performance. Typically, these sheets feature a width of approximately 1.1 meters, with the length set at a standard 3.6 meters—an ideal measurement for various applications, from small garden sheds to expansive industrial warehouses. This length strikes a perfect balance, providing sufficient coverage without overwhelming the project site or complicating transportation.

- Ease of handling and transport, fitting comfortably into standard vehicles

- Minimal wastage during installation, reducing overall project costs

- Enhanced weatherproofing through consistent overlap configurations

Ideal Applications for 3.6m Sheets

Corrugated roof sheets 3.6m are a versatile choice for a wide range of roofing projects across South Africa. Their length makes them ideal for both small structures and large industrial buildings, offering consistent coverage with minimal waste. These sheets are especially popular because their size simplifies handling and transportation, fitting comfortably into standard vehicles and reducing logistical costs.

Many builders and property owners favor corrugated roof sheets 3.6m for their durability and ease of installation. Their length allows for seamless overlaps, which significantly enhance weatherproofing against South Africa’s intense sun and sudden downpours. This makes them perfect for applications such as:

- Garden sheds and outdoor storage units

- Large-scale industrial warehouses

<li Residential extensions and carports

Whether constructing a small backyard structure or a sizeable commercial roof, corrugated roof sheets 3.6m offer the perfect balance of coverage, strength, and affordability. Their dimensions are thoughtfully designed to meet the demands of diverse building requirements, ensuring a reliable and long-lasting roofing solution.

Comparison with Other Lengths

When comparing corrugated roof sheets 3.6m to other lengths, the distinction often lies in their unparalleled balance of versatility and efficiency. While shorter sheets, such as 2.4m or 3.0m, are more manageable for small-scale projects, they tend to increase the number of joints needed, which can compromise weatherproofing. Conversely, longer sheets like 4.8m or 6.0m may offer fewer overlaps but pose logistical challenges during handling and transportation.

Corrugated roof sheets 3.6m strike a remarkable compromise—long enough to reduce the number of joints, yet manageable enough to facilitate straightforward installation. This length also minimizes waste, ensuring that material costs are kept in check—an important consideration for any project, big or small. For builders and property owners in South Africa, this specific length often proves to be the most practical choice, accommodating a wide range of roofing needs with minimal fuss.

- Ease of handling during installation enhances productivity and safety on-site.

- Reduced waste translates into cost savings and more sustainable building practices.

- The optimal length for seamless overlaps enhances weatherproofing, especially in South Africa’s unpredictable climate.

Understanding how corrugated roof sheets 3.6m compare with other lengths allows for smarter decisions—aligning project requirements with the best possible material choice. These sheets exemplify the perfect harmony between practicality and performance, making them a staple in roofing solutions across diverse sectors in South Africa.

Materials and Types of Corrugated Roof Sheets

Metal Corrugated Sheets

Corrugated roof sheets 3.6m are a popular choice for both commercial and residential structures in South Africa. Their durability and ease of installation make them ideal for a wide range of applications. When selecting the right material, it’s important to understand the different types of corrugated roof sheets available on the market.

Metal corrugated sheets are among the most common due to their strength and longevity. These sheets are typically made from galvanized steel, aluminum, or zinc-coated materials, providing excellent resistance to weathering and corrosion. The versatility of metal corrugated sheets allows for various finishes, from plain galvanized to painted or coated options, adding an extra layer of protection and aesthetic appeal.

In particular, corrugated roof sheets 3.6m are favored because they strike a balance between ease of handling and coverage. They can be tailored to suit specific project needs, whether for a small shed or a large industrial roof. The choice of material and type directly influences the lifespan and performance of the roofing system, making it essential to select the best option based on your local climate and structural requirements.

PVC and Plastic Options

In the shadowed realm of roofing options, the choice of materials can seem as ominous as the darkness that cloaks the night. Corrugated roof sheets 3.6m, however, offer a beacon of versatility amidst this gloom. Among the myriad options, PVC and plastic corrugated sheets emerge as compelling alternatives for those seeking lightweight resilience and a touch of modernity. These materials are often cast in monochrome hues, but their true charm lies in their resistance to the relentless South African elements, defying rust and decay with an almost supernatural resilience.

Unlike their metal counterparts, PVC and plastic corrugated roof sheets 3.6m are remarkably easy to install — almost as if they were forged by some arcane craft. Their flexibility permits a seamless adaptation to curved and irregular surfaces, whispering promises of durability and aesthetic appeal. For structures where weight is a concern or where budget constraints loom large, these sheets offer an affordable yet surprisingly enduring solution. In the end, the choice of material becomes a dance with the shadows—balancing strength, longevity, and the whisper of the unknown.

Asbestos-Free Alternatives

When exploring the realm of sustainable roofing options, asbestos-free alternatives stand out like a breath of fresh, ozone-friendly air. Traditional asbestos sheets, once the stalwart of durability, have been relegated to history books due to health concerns. Today, materials such as fiber cement and high-quality polycarbonate dominate the scene, offering longevity without compromising safety. These materials are crafted to withstand the unpredictable South African climate, from blistering sun to torrential rain, ensuring your structure remains resilient for years to come.

Among the myriad options, corrugated roof sheets 3.6m made from fiber cement or advanced plastics are particularly noteworthy. Their robust composition guarantees resistance to corrosion, UV damage, and even the occasional hailstorm. For those seeking a comprehensive solution, some manufacturers now provide a variety of textures and finishes, mimicking traditional materials but with a modern twist. The choice of material influences not only the lifespan but also the aesthetic appeal, making these sheets a flexible choice for diverse architectural visions.

- Fiber cement sheets – renowned for their strength and fire resistance, these sheets are a popular asbestos-free alternative.

- Polycarbonate sheets – lightweight, transparent, and UV-resistant, perfect for allowing natural light into the space beneath.

- Reinforced plastic options – offering exceptional durability and minimal maintenance, ideal for various applications.

In the pursuit of the perfect roofing solution, understanding the material’s composition and its suitability for your specific environment is paramount. Corrugated roof sheets 3.6m, available in a spectrum of asbestos-free options, embody the evolution of roofing technology—melding safety, style, and substance seamlessly.

Benefits of Choosing 3.6m Corrugated Roof Sheets

Ease of Installation

Choosing corrugated roof sheets 3.6m offers a remarkable blend of practicality and efficiency that’s hard to beat. These sheets are designed to minimize installation time, making them an ideal choice for both commercial and residential projects across South Africa. Their manageable length allows for easier handling, reducing the need for specialized equipment or extra manpower. This translates into substantial savings on labour costs and project timelines.

The ease of installation is further enhanced by their lightweight yet durable construction. With fewer joints and fewer cuts needed, corrugated roof sheets 3.6m streamline the roofing process. For those undertaking DIY projects or seeking quick upgrades, this length simplifies alignment and fastening, ensuring a secure fit without fuss. It’s a testament to how modern manufacturing has optimized these sheets for straightforward, fuss-free installation—making them a popular choice for builders and homeowners alike!

Durability and Longevity

When investing in corrugated roof sheets 3.6m, durability and longevity are paramount. These sheets are engineered to withstand the harsh South African climate, from scorching sun to heavy rains. Crafted from high-quality galvanized steel or coated aluminium, they resist corrosion and rust, ensuring your roof remains steadfast for decades. Their robust construction means they can endure extreme weather conditions without warping or cracking—a true testament to their resilience.

Moreover, corrugated roof sheets 3.6m offer exceptional longevity, often exceeding 20 years with minimal maintenance. This durability translates into significant savings over time, as replacement costs are minimized. For added peace of mind, many products come with comprehensive warranties, reaffirming their status as a reliable roofing solution. Whether for a sprawling industrial complex or a cozy home, choosing these sheets guarantees a steadfast shield against South Africa’s unpredictable climate.

Cost-Effectiveness

When pondering the true value of corrugated roof sheets 3.6m, one quickly realizes that cost-effectiveness is not merely about initial expenditure but the long-term savings it facilitates. These sheets, with their optimal length, strike a delicate balance—neither too short to necessitate excessive joins nor overly long, which complicates handling and installation. This thoughtful dimension translates into significant savings, especially when covering large expanses in South Africa’s unpredictable climate.

In addition, the affordability of corrugated roof sheets 3.6m extends beyond the purchase price. Their straightforward installation process reduces labor costs, meaning less time on-site and fewer expenses. Many suppliers offer bulk discounts for larger projects, making them a savvy choice for both industrial giants and humble homesteads. The resilience of these sheets ensures minimal maintenance, further enhancing their reputation as a genuinely economical roofing option.

- Reduced installation time due to manageable length

- Lower maintenance costs thanks to high durability

- Potential discounts for bulk purchases

- Extended lifespan, often surpassing two decades

By choosing corrugated roof sheets 3.6m, property owners in South Africa not only invest in a resilient roofing solution but also embrace a pragmatic approach to budget management. The blend of durability, ease of installation, and affordability makes these sheets an undeniably cost-effective choice—proving once again that good things do come in well-sized packages.

Weather Resistance

In the realm of roofing, where the elements conspire to test our resolve, the weather resistance of corrugated roof sheets 3.6m emerges as a silent guardian. These sheets, crafted from resilient metals or durable plastics, stand firm against South Africa’s unpredictable climate — a testament to their formidable strength. Rain, hail, or blazing sun, they shield with an unwavering resolve that whispers tales of endurance.

What truly elevates their virtue is their ability to withstand the relentless assault of time and nature. Their surface, often treated with protective coatings, repels corrosion and resists fading, ensuring the integrity of your shelter endures beyond mere decades. This weather resistance not only preserves the structural sanctity but also reduces maintenance worries, allowing property owners to rest easy.

- Exceptional resistance to corrosion and rust

- Ability to withstand extreme temperature fluctuations

- Protection against hail and heavy storms

Choosing corrugated roof sheets 3.6m means embracing a shield forged by nature’s fiercest whims, an armor that blends practicality with poetic resilience. Their weather resistance transforms a simple roof into a bastion against the caprice of South Africa’s skies, ensuring that your investment remains steadfast amidst the chaos of the elements.

Installation Tips and Best Practices

Preparing the Roof Frame

Installing corrugated roof sheets 3.6m may seem straightforward, but the true mastery lies in preparation. A meticulously prepared roof frame is the foundation of a durable, weather-resistant roof. Skimp on this step, and even the most robust corrugated roof sheets 3.6m can falter under relentless South African sun and rain. Take the time to inspect the frame for any signs of rot, rust, or warping—these imperfections can compromise the entire structure.

Ensuring proper alignment is paramount. A level surface not only guarantees aesthetic appeal but also prevents unnecessary stress on the sheets during installation. Here’s a quick guide to prepare your roof frame:

- Clear the surface of debris and loose materials.

- Check for structural integrity—replace or reinforce weak sections.

- Ensure the frame is level and square—use a spirit level for precision.

- Secure the frame firmly to withstand wind loads, especially in areas prone to storms.

By paying attention to these foundational details, you set the stage for seamless installation and the long-term performance of your corrugated roof sheets 3.6m. Remember, the strength of your roof begins with the integrity of its frame—skip this step at your own peril!

Proper Overlapping Techniques

In the shadowed realm of roofing, where the elements conspire to test the resilience of construction, proper installation of corrugated roof sheets 3.6m becomes an art of dark precision. A misstep in overlapping techniques can transform a sturdy canopy into a fragile illusion—an unintended gateway for rain and wind to breach the fortress. Ensuring correct overlap is not merely a matter of aesthetics but a safeguard against the relentless South African storms that threaten to unravel even the most robust structures.

When installing corrugated roof sheets 3.6m, embrace a methodical approach: begin by staggering overlaps by at least one corrugation, which helps channel water away from vulnerable seams. As you lay each sheet, remember to secure them with fasteners placed in the troughs, avoiding the peaks where water can pool. This technique minimizes the risk of leaks and prolongs the lifespan of your roof, whispering promises of longevity amidst the chaos of weather.

To elevate your craftsmanship, consider these steps:

- Align each sheet meticulously to ensure uniform overlaps.

- Use a spirit level to maintain a true, level surface—imperative for seamless water runoff.

- Fasten sheets firmly, yet avoid overtightening, which can cause warping or cracking.

Paying homage to the dark poetry of construction, proper overlapping techniques for corrugated roof sheets 3.6m forge a barrier of resilience—an armor forged in precision and patience, standing resilient against the bitter South African elements.

Fastening and Securing Methods

When it comes to fastening corrugated roof sheets 3.6m, precision is paramount. A secure attachment ensures your roof withstands the relentless South African storms, where gale-force winds and heavy rains are a daily threat. Proper securing methods not only prevent leaks but also extend the lifespan of your roofing investment, making it a crucial step in the installation process.

Start by selecting the right fasteners—preferably corrosion-resistant screws designed specifically for metal or PVC corrugated roof sheets 3.6m. Place them in the troughs, not the peaks, to avoid water pooling and potential leaks. Tighten each fastener just enough to hold the sheet firmly, but beware of overtightening, which can cause warping or cracking. Remember, a well-secured sheet acts as a shield—resilient against the elements and ready to stand the test of time.

For optimal security, consider using a combination of screws and washers, especially in areas prone to high winds. This layered approach ensures your corrugated roof sheets 3.6m stay in place, even during South Africa’s most ferocious weather events. The key lies in meticulous attention to fastening techniques—each action imbued with the quiet promise of durability and strength.

Safety Precautions During Installation

When installing corrugated roof sheets 3.6m, safety is not just a precaution—it’s the very foundation of a successful project. The South African climate demands vigilance; gusts of wind and unexpected storms can turn a precarious setup into a perilous gamble. Ensuring proper safety precautions during installation transforms a routine task into a fortress of resilience. Always wear appropriate protective gear—helmets, gloves, and sturdy footwear—because the roof’s ascent is a climb into the unknown where every step must be deliberate.

To mitigate risk and maintain structural integrity, consider employing fall protection systems such as harnesses and guardrails. As you work, remember that meticulous attention to detail is paramount. Secure the sheets with the right fasteners, and double-check each one before moving to the next phase. For added security, especially in high-wind zones, a layered fastening approach with washers can serve as a safeguard against the unpredictable South African weather.

Engaging in this task with both caution and precision elevates the integrity of your installation. A seamless combination of safety measures and best practices ensures your corrugated roof sheets 3.6m not only withstand the elements but do so with grace and durability. After all, every bolt tightened and every sheet laid is a testament to craftsmanship—an ode to resilience in the face of nature’s relentless power.

Maintenance and Care for Corrugated Roof Sheets

Regular Cleaning

Maintaining the pristine appearance and structural integrity of corrugated roof sheets 3.6m requires a gentle touch and consistent care. Over time, dirt, moss, and debris can accumulate, dulling the vibrant sheen of these durable sheets. Regular cleaning is essential to prevent the build-up of grime that can compromise both aesthetics and longevity. A soft broom or a low-pressure hose can effectively remove surface dirt without risking damage to the corrugated profile.

For more stubborn stains or algae growth, a mild detergent mixed with water can be used to restore the roof’s luster. It’s important to avoid harsh chemicals that might corrode metal or degrade PVC options. Additionally, inspecting the sheets periodically for signs of rust or corrosion ensures early intervention, preserving the lifespan of the corrugated roof sheets 3.6m.

- Remove loose debris

- Wash with gentle detergent

- Rinse thoroughly

Implementing these simple yet crucial steps keeps your roofing investment looking magnificent and functioning flawlessly for years to come.

Inspecting for Damage

Inspecting corrugated roof sheets 3.6m for damage is an essential ritual in the stewardship of your roofing investment. Over time, even the most resilient sheets can fall prey to the caprices of weather—hail, wind, or relentless sun—that might cause dents, cracks, or corrosion. A keen eye is your best ally; regular visual checks can unearth early signs of trouble before they escalate into costly repairs. Look for rust spots, loose fasteners, or warped sections that could compromise the integrity of your roof.

To facilitate thorough inspections, consider adopting a systematic approach. For instance, a simple

- walk the length of the roof

- check for loose or missing screws

- examine overlapping seams

—these steps ensure no detail is overlooked. Remember, the longevity of corrugated roof sheets 3.6m depends on timely detection of damage, preventing minor issues from snowballing into structural dilemmas. After all, a vigilant homeowner or maintenance professional can extend the lifespan of these sheets and keep your property looking impeccable, no matter the weather’s whims.

Repairing Cracks or Dents

Maintaining corrugated roof sheets 3.6m requires more than just periodic cleaning—it demands vigilant care to preserve their structural integrity. When cracks or dents appear, they can silently undermine the entire roofing system, turning a minor flaw into a major catastrophe. Addressing these issues promptly is crucial to avoid costly repairs and extend the lifespan of your roof.

For repairing cracks or dents, start by assessing the damage thoroughly. Small cracks can often be sealed with specialized roofing sealants, ensuring a watertight barrier. For larger dents, it might be necessary to replace the affected section or reinforce the area with additional fastening. Remember, a seamless repair maintains the weather-resistant properties of corrugated roof sheets 3.6m, preventing leaks and corrosion from taking hold.

Regular inspections should be complemented with proper maintenance routines. Applying a protective coating or paint can shield the material from harsh South African weather, especially in areas prone to intense sun or heavy rain. Keep an eye out for loose fasteners or warped sections, which, if left unattended, can lead to more severe damage. Consistent care transforms a good roof into an enduring shield against the elements.

In essence, caring for corrugated roof sheets 3.6m isn’t just about aesthetics—it’s about safeguarding your entire property. With diligent upkeep and swift repairs, these sheets can withstand the relentless South African climate, ensuring your investment remains resilient and reliable for years to come.

Protective Coatings and Treatments

Protecting the longevity of corrugated roof sheets 3.6m demands more than routine inspections; it requires strategic application of protective coatings and treatments that fortify them against South Africa’s capricious climate. These coatings serve as a resilient barrier, shielding the metal or PVC from relentless UV radiation, heavy rainfall, and corrosive elements that threaten structural integrity. A well-chosen protective layer not only enhances durability but also preserves the aesthetic appeal, ensuring the roof remains visually appealing for years to come.

Applying a high-quality, weather-resistant paint or sealant can transform the lifespan of your corrugated roof sheets 3.6m. Regularly renewing these surface treatments creates a formidable shield that actively repels moisture and inhibits rust formation. For optimal results, consider a coating with UV stabilizers—crucial in regions with intense sunlight—thereby reducing the risk of thermal expansion and material degradation over time.

In some cases, a specialized anti-corrosion treatment can be injected into vulnerable seams and fastener points, further reinforcing the roof’s resistance against the relentless South African elements. For added assurance, a periodic reapplication—at least every few years—can significantly extend the service life of corrugated roof sheets 3.6m, transforming maintenance from a chore into a proactive safeguard. After all, the true strength of your roofing system lies not only in its initial installation but also in the enduring care it receives through consistent protective treatments.

Cost Considerations and Budgeting

Pricing Factors for 3.6m Corrugated Sheets

When planning a roofing project with corrugated roof sheets 3.6m, understanding the cost considerations is crucial for staying within budget without compromising quality. The initial expense often hinges on the material choice—metal, PVC, or eco-friendly alternatives—all of which influence overall pricing. Metal corrugated sheets tend to be more durable but come at a higher price point, while PVC options offer affordability with decent weather resistance.

Pricing factors also include the complexity of the installation site, such as the ease of access and the structural requirements of the roof frame. Typically, the cost per sheet decreases with larger quantities, making bulk purchases a savvy move for large-scale projects. To help visualize this, consider the following:

- Material type and quality

- Length and width of the sheets

- Ease of installation and labor costs

- Additional protective coatings or treatments

By carefully weighing these factors, property owners in South Africa can make informed decisions that balance durability and affordability when choosing corrugated roof sheets 3.6m for their roofing needs. With the right planning, your roof can withstand the harsh African climate while remaining budget-friendly—truly a testament to both craftsmanship and resilience.

Cost vs. Quality

When budgeting for corrugated roof sheets 3.6m, it’s tempting to chase the lowest price—after all, who doesn’t love a good bargain? But in the world of roofing, skimping on quality can lead to costly headaches down the line. Balancing cost versus durability is a delicate dance, especially in South Africa’s unpredictable climate. The key is understanding that higher-quality corrugated roof sheets 3.6m, often made from galvanized metal or eco-friendly materials, might carry a heftier price tag upfront but can save you money over time by resisting rust, weather damage, and wear.

To keep your project within budget without sacrificing quality, consider the following:

- Material choice—metal tends to be more durable but pricier, while PVC offers a wallet-friendly alternative.

- Installation complexity—hard-to-reach roofs or intricate structures can ramp up labor costs significantly.

- Bulk purchasing—buying corrugated roof sheets 3.6m in larger quantities often nets you discounts, making it a savvy investment for big projects.

In essence, a well-planned budget that weighs these factors ensures your roof stands tall against the African elements while keeping your finances in check. It’s the smart way to blend resilience with affordability—because nobody enjoys a leaky, costly roof over their head!

Getting Quotes and Comparing Suppliers

When it comes to budgeting for corrugated roof sheets 3.6m, the old adage “you get what you pay for” rings truest of all. Cutting corners in the pursuit of a bargain might seem like a smart move initially, but in South Africa’s capricious climate, a cheap sheet can turn into a costly disaster faster than you can say “roof leak.” To avoid financial and structural headaches, it’s critical to get multiple quotes from reputable suppliers. Comparing prices alone can be misleading, as some providers offer rock-bottom rates that hide dubious quality or hidden costs. Instead, focus on the value—materials, thickness, and warranty—these are your best indicators of long-term durability.

Getting quotes from different suppliers for corrugated roof sheets 3.6m can seem tedious, but it’s an investment in peace of mind. A simple ordered list can help streamline your decision-making process:

- Request detailed quotes that specify the material type, thickness, and coating.

- Ask about delivery costs—sometimes the lowest quote excludes hefty shipping fees.

- Inquire about bulk discounts if you’re planning a large roofing project.

Remember, the cheapest option might save you a few rand upfront but could cost you dearly in repairs and replacements down the line. Balancing costs with quality, and comparing suppliers thoroughly, ensures your corrugated roof sheets 3.6m not only fit your budget but also withstand the relentless South African elements for years to come. After all, a well-chosen sheet is an investment in resilience—because nobody wants a leaky roof that turns your home into an indoor swimming pool!

Where to Buy Corrugated Roof Sheets 3.6m

Local Suppliers and Distributors

For those seeking to transform their roofing projects into a tapestry of resilience and elegance, finding reliable sources for corrugated roof sheets 3.6m is paramount. South Africa boasts a vibrant market of local suppliers and distributors who cater to diverse needs, from modest DIY ventures to expansive commercial undertakings. The allure of sourcing from nearby vendors lies not only in prompt delivery but also in the personalized service that ensures your corrugated roof sheets 3.6m fit perfectly into your vision.

Many seasoned builders and homeowners turn to trusted local suppliers, where quality is guaranteed and prices remain competitive. These vendors often stock a variety of materials, including galvanized steel, PVC, and fiber cement options, all designed to withstand South Africa’s demanding weather patterns. To streamline your search, consider the following steps:

- Visit local hardware stores and building material outlets, which frequently carry a curated range of corrugated roof sheets 3.6m.

- Consult with regional distributors who specialize in roofing solutions—these often offer bulk discounts and expert advice tailored to your project.

- Explore online directories and trade platforms to compare prices, availability, and delivery options from nearby suppliers.

Whether you prefer the tactile assurance of physically inspecting your corrugated roof sheets 3.6m or the convenience of online ordering, South Africa’s market is rich with options designed to meet your unique needs. With a bit of local knowledge, your roofing endeavor becomes not just a task but a journey into craftsmanship and community connection.

Online Retailers

In the digital age, where convenience meets variety, sourcing corrugated roof sheets 3.6m online has become a seamless journey, much like a river flowing effortlessly toward its destination. South African homeowners and builders alike turn to trusted online retailers to find that perfect blend of quality and affordability. The vast landscape of e-commerce platforms offers an array of options, each promising durability, style, and swift delivery—turning what once was a chore into an experience of discovery.

Popular online retail platforms such as Builders Warehouse, Takealot, and eRoofing provide extensive catalogs of corrugated roof sheets 3.6m. These sites often feature detailed specifications, customer reviews, and competitive pricing, empowering buyers to make informed decisions. For those seeking tailored solutions, many platforms also offer the chance to compare various materials—galvanized steel, PVC, or fiber cement—ensuring your project’s needs are met with precision.

To streamline your search, consider browsing through the following steps:

- Review product descriptions carefully for thickness, coating, and material quality.

- Utilize filter options to narrow down your preferred length, color, and price range.

- Check delivery terms and availability to ensure your corrugated roof sheets 3.6m arrive on schedule.

Whether you prefer the tactile reassurance of inspecting sheets in person or the convenience of clicking through a virtual marketplace, online retailers in South Africa are equipped to serve your roofing ambitions with ease and reliability. The digital realm unlocks a universe of possibilities—where your next project is just a few clicks away, wrapped in the promise of quality and efficiency.

Wholesale Purchasing Options

For those seeking to purchase corrugated roof sheets 3.6m in bulk, wholesale options present an attractive pathway to both quality and cost savings. South African suppliers and distributors recognize the importance of offering competitive prices without compromising durability, making wholesale purchasing a strategic move for large-scale projects or ongoing maintenance needs. Accessing these wholesale suppliers often means establishing relationships with local manufacturers or regional distributors who understand the nuances of the South African construction landscape.

Many suppliers operate on a model that prioritizes volume sales, providing discounts for bulk orders of corrugated roof sheets 3.6m. This not only reduces project costs but also ensures uniformity across roofing installations, which is essential for large commercial or agricultural structures.

- Local manufacturers

- Regional distributors

- Specialized roofing wholesalers

are prime sources for wholesale buying, and their extensive networks facilitate swift delivery and reliable supply chains.

Online platforms also serve as valuable portals for wholesale purchasing, offering detailed catalogs and flexible order quantities designed specifically for bulk buyers. Whether you’re a contractor, builder, or DIY enthusiast, exploring these avenues can unlock significant savings and streamline procurement processes. In choosing your supplier, always consider their reputation for quality and consistency—especially when sourcing corrugated roof sheets 3.6m in large quantities—because long-term durability depends on it.

Environmental Impact and Sustainability

Recyclability of Corrugated Roof Sheets

Amid the rising tide of environmental consciousness, the sustainability of building materials has become more than a mere consideration—it is a moral imperative. Corrugated roof sheets 3.6m, often heralded for their durability and versatility, also occupy a pivotal role in eco-friendly construction. Their recyclability means they can be repurposed time and again, minimizing waste and reducing the carbon footprint associated with manufacturing new materials.

Most notably, many corrugated roof sheets 3.6m are manufactured from materials like galvanized steel or recyclable plastics, which lend themselves to sustainable practices. These options not only support eco-conscious building but also align with green building standards prevalent across South Africa. The ability to recycle these sheets at the end of their lifespan ensures that they contribute positively to the environment rather than burden landfills.

- Recyclable metals like steel and aluminum

- Low-impact manufacturing processes

- Extended lifespan reducing replacement frequency

In an era where sustainability is more than a trend but a necessity, choosing corrugated roof sheets 3.6m offers a harmonious blend of resilience and respectful stewardship of our planet. Their eco-friendly profile makes them an attractive option for forward-thinking builders and homeowners alike, eager to embrace a greener future without compromising on quality or performance.

Eco-Friendly Material Choices

In an era where environmental impact weighs heavily on every construction decision, the sustainability of materials like corrugated roof sheets 3.6m becomes increasingly vital. These roofing solutions are not only resilient and cost-effective but also champion eco-friendliness through their recyclable nature. By choosing corrugated roof sheets 3.6m, builders and homeowners support a sustainable future, reducing waste and conserving natural resources.

Their eco-friendly profile is amplified by the fact that most corrugated roof sheets 3.6m are made from recyclable metals such as galvanized steel or durable plastics, which lend themselves to multiple reuse cycles. This means that at the end of their lifespan, these sheets can be repurposed rather than discarded, minimizing landfill contributions. Additionally, their manufacturing processes often involve low-impact methods that further diminish environmental harm.

- Extended lifespan reduces the frequency of replacement, lessening material consumption and waste.

Choosing corrugated roof sheets 3.6m aligns with green building standards, supporting environmentally conscious development across South Africa. Their recyclability and sustainable material choices make them an optimal option for those committed to reducing their ecological footprint while maintaining quality and durability. As more construction projects adopt eco-friendly practices, corrugated roof sheets 3.6m stand out as a conscientious choice that marries resilience with respect for our planet.

Reducing Waste During Installation

In the delicate dance between human ambition and Mother Earth’s enduring patience, the choice of roofing materials becomes a testament to our commitment to sustainability. Corrugated roof sheets 3.6m, with their eco-friendly profile, exemplify this harmony—melding durability with environmental consciousness. When installed thoughtfully, these sheets do more than shelter; they actively reduce waste, preserving precious resources for generations to come.

During installation, careful planning ensures minimal material wastage. Every cut and fit is a calculated act, aligning with the principle of reducing waste. Instead of discarding excess, leftover pieces can often be repurposed—becoming part of another project or recycled into new products. This approach not only conserves natural resources but also diminishes the environmental footprint associated with manufacturing and disposal.

Furthermore, the recyclable nature of corrugated roof sheets 3.6m—primarily made from galvanized steel or durable plastics—means they can be reprocessed multiple times. At the end of their lifespan, these sheets do not contribute to overflowing landfills but instead find new life through recycling initiatives. Such practices exemplify a commitment to a circular economy, where sustainability is woven into every phase of the product’s lifecycle.

As more South African builders and homeowners embrace environmentally conscious construction, the significance of reducing waste during installation becomes increasingly clear. Corrugated roof sheets 3.6m stand as a resilient, eco-friendly choice—supporting not just a sturdy roof but a sustainable future rooted in mindful resource use and waste reduction.

0 Comments