Understanding Roof Sheet Unit Weight

Definition of Roof Sheet Unit Weight

When considering the structural integrity and overall durability of a building, understanding the roof sheet unit weight becomes paramount. This measurement not only influences the choice of roofing materials but also affects transportation, installation, and long-term performance. In essence, the roof sheet unit weight refers to the mass of a specific quantity of roof sheet material, typically expressed in kilograms per square metre (kg/m²). This seemingly simple figure holds significant weight in architectural planning and engineering calculations, guiding decisions that ensure safety and efficiency.

By grasping the nuances of roof sheet unit weight, stakeholders can better anticipate load-bearing requirements and optimise material selection. For example, lighter roof sheets may reduce the structural burden but could compromise durability, while heavier options might offer enhanced longevity at the expense of increased installation costs. Ultimately, the balance achieved through a precise understanding of this measurement ensures a resilient and sustainable roofing solution that meets both aesthetic and functional demands.

Importance in Construction and Design

Understanding roof sheet unit weight is crucial in construction and design. It directly impacts the load-bearing capacity of a structure and influences material choices. A slight miscalculation can lead to costly modifications or, worse, structural failure. That’s why precise knowledge of roof sheet unit weight helps engineers and architects optimise safety and efficiency.

This measurement guides decisions around material selection, especially when balancing durability with cost. Lighter roof sheets reduce overall structural stress but may lack longevity, while heavier options provide resilience at a greater installation expense. Recognising these trade-offs ensures a resilient, cost-effective roofing system that aligns with project demands.

Incorporating the right roof sheet unit weight also affects transportation and installation. Heavier sheets demand specialised handling, increasing logistical complexity. Conversely, lighter materials streamline the process, saving time and labour costs. Knowing this key metric helps stakeholders create sustainable, long-lasting roofs tailored to specific climate and aesthetic requirements.

Factors Influencing Roof Sheet Weight

Understanding what influences roof sheet unit weight is essential for making informed decisions in construction. Several factors play a role, from material composition to manufacturing processes. The type of material, whether metal, fibre cement, or polycarbonate, directly impacts the weight. Thicker sheets tend to be heavier, but they also offer increased durability.

Environmental conditions and aesthetic preferences can also influence the choice. For example, regions prone to heavy snow require sturdier, heavier sheets to withstand the load. Conversely, lightweight options are preferred for quick installation and reduced structural stress. Recognising these factors allows architects and engineers to optimise the balance between strength and efficiency.

In some cases, the roof sheet unit weight can be affected by additional coatings or treatments that add to the overall mass. When selecting the ideal roofing material, it’s crucial to consider these variables to ensure the final design performs optimally under specific conditions. After all, the right understanding of roof sheet unit weight can mean the difference between a resilient, cost-effective roof and one that falls short of expectations.

Types of Roofing Sheets and Their Typical Weights

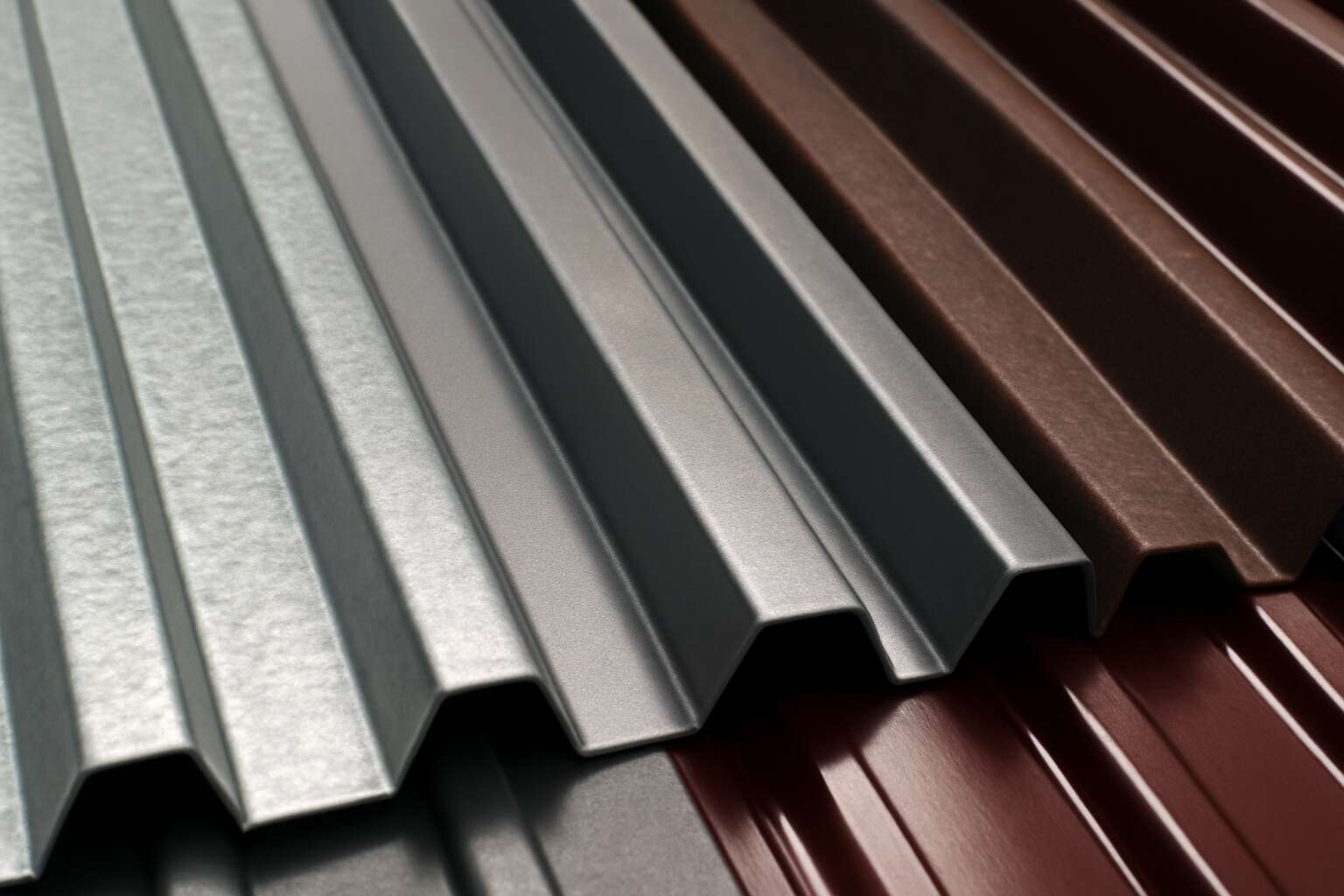

Metal Roofing Sheets

In the realm of roofing, the variety of metal roofing sheets offers more than just aesthetic appeal; it embodies a spectrum of weights that influence both design and durability. The roof sheet unit weight, an often-underestimated detail, varies significantly depending on the material and profile. For instance, aluminium sheets tend to be lighter, typically around 3 to 4 kg/m², while steel alternatives can range from 4.5 to 8 kg/m², depending on thickness and coating.

Understanding the typical weights of these roofing sheets helps architects and builders strike a delicate balance between robustness and ease of installation. Different types of roofing sheets—such as corrugated, ribbed, or standing seam—each possess unique weight characteristics that influence structural support requirements. Metal roofing sheets, celebrated for their longevity and sleek aesthetic, are particularly notable for their versatile roof sheet unit weight, which can be fine-tuned to meet specific project needs.

To clarify, here are some common types of metal roofing sheets and their typical weights:

- Corrugated galvanised steel – approximately 4.5 to 6 kg/m²

- Standing seam aluminium – around 3 to 4 kg/m²

- Profiled zinc sheets – roughly 4 to 5 kg/m²

This spectrum of weights underscores the importance of selecting the right roofing sheet to ensure both structural integrity and aesthetic harmony. The delicate interplay between material choice and roof sheet unit weight shapes the very soul of a building’s roof—light enough to dance, yet resilient enough to withstand the storms of time.

Asphalt Shingles

Among the diverse landscape of roofing options, asphalt shingles stand out not only for their affordability but also for their surprisingly broad range of roof sheet unit weights. Unlike metal sheets, asphalt shingles are composed of a fibreglass or organic mat coated with asphalt and mineral granules, resulting in a different weight profile altogether. Typically, asphalt shingles weigh around 10 to 14 kg/m², making them notably heavier than many metal roofing sheets.

This added weight plays a crucial role in their application, influencing both the installation process and the structural support needed. Asphalt shingles are often chosen for residential projects because of their ease of layering and adaptability, but understanding their roof sheet unit weight ensures that the supporting framework is adequately fortified. For architects and builders, recognising these weight distinctions helps in designing roofs that balance durability with practicality, especially when considering factors like wind uplift resistance and longevity.

Here’s a quick overview of common roofing sheet types and their typical weights:

- Asphalt shingles – approximately 10 to 14 kg/m²

- Metal roofing sheets – generally between 3 and 8 kg/m²

- Clay tiles – around 45 to 55 kg/m²

The varied roof sheet unit weight of asphalt shingles and their counterparts underscore the importance of precise material selection, ensuring structures are both resilient and efficient in their design. The choice hinges not just on aesthetics but on the nuanced interplay between weight, support, and environmental resilience. Each layer, each material, whispers a story of engineering mastery—an intricate dance of weight and strength that defines the very essence of a well-crafted roof.

Clay and Concrete Tiles

Clay and concrete tiles evoke images of timeless elegance, yet their substantial weight cannot be overlooked. These roofing materials are among the heaviest options, with typical weights ranging from 45 to 55 kg/m². Their density offers durability and a majestic appearance, but it also means that the roof’s supporting structure must be meticulously designed to bear this hefty load. This is where understanding the roof sheet unit weight becomes vital—it’s the silent force dictating the resilience of your roof.

Compared to lighter alternatives, clay and concrete tiles demand a stronger framework, often requiring reinforced trusses and load-bearing walls. The sheer mass of these tiles acts as a natural insulator, helping to regulate temperature and withstand harsh weather conditions. For architects and builders, selecting the right roofing sheet based on its weight isn’t just a matter of aesthetics; it’s a strategic decision that impacts every layer of your roofing project.

- Weighty but robust, clay and concrete tiles serve as a testament to engineering mastery, with their impressive roof sheet unit weight offering longevity and resistance.

PVC and Plastic Roofing Sheets

Among the myriad of roofing options, PVC and plastic roofing sheets stand out as lightweight champions, often transforming the architectural landscape with their versatility. Their roof sheet unit weight typically ranges from 3 to 8 kg/m², making them ideal for projects where weight minimisation is paramount. This slender profile not only simplifies structural requirements but also accelerates installation, reducing labour costs and project timelines.

Unlike their heavier counterparts, PVC and plastic sheets offer a surprising robustness, with modern manufacturing techniques ensuring durability against the elements. For those seeking a balance between strength and ease of handling, these sheets often feature a corrugated or flat design, each with distinct weight characteristics. For instance, corrugated plastic roofing can weigh around 4 to 6 kg/m², providing a resilient barrier against weather while remaining unobtrusively light.

- Ease of installation

- Cost-effective in both material and labour

- Flexible design options

Understanding the roof sheet unit weight of PVC and plastic roofing is essential for precise structural planning. It influences not only the overall load on the building but also the choice of supporting framework and insulation considerations. In essence, lighter roofing sheets like these challenge traditional notions of durability, proving that strength can be redefined by innovation and thoughtful design.

Composite Roofing Materials

In the realm of roofing materials, the spectrum of composite roofing materials presents a fascinating mosaic of choices, each with distinct weight characteristics that influence construction and design. These roofing sheets are often crafted to balance durability with lightweight properties, ensuring structural integrity without burdening the building’s framework. Among them, materials like aluminium-polymer composites and fibre-reinforced plastics stand out, boasting roof sheet unit weights that typically range from 2 to 6 kg/m². Such lightness facilitates swift installation and reduces the need for extensive supporting structures, making them a favourite in modern architectural ventures.

For those exploring options beyond traditional heavyweights, understanding the typical weights of different composite roofing materials becomes crucial. An ordered list can help clarify their comparative advantages:

- Aluminium-polymer composites: 2-4 kg/m², renowned for their resilience and ease of handling.

- Fibre-reinforced plastics: 3-5 kg/m², offering excellent strength-to-weight ratios.

- Glass fibre panels: 4-6 kg/m², providing an ideal balance of durability and lightweight construction.

These figures underscore how the roof sheet unit weight varies significantly across composite roofing materials, allowing architects and builders to select options tailored to their structural and aesthetic needs. The allure of lightweight composite roofing lies in its ability to redefine durability and design flexibility, transforming rooftops into canvases of innovation and efficiency.

Measuring and Calculating Roof Sheet Unit Weight

Standard Units of Measurement

Understanding how to measure and calculate roof sheet unit weight is essential for ensuring structural integrity and optimal performance. The process begins with selecting the appropriate standard units of measurement, typically expressed in kilograms per square metre (kg/m²) or pounds per square foot (lb/ft²). These units provide a consistent basis for comparison across different materials and designs, making sure that every sheet fits seamlessly into the larger architectural vision.

To accurately determine the roof sheet unit weight, a combination of precise weighing and surface area measurement is required. For instance, weighing a sample sheet and dividing that weight by its surface area yields the fundamental unit weight. When working with various roofing materials—such as metal, asphalt, or clay tiles—be mindful that the typical ranges can vary significantly. A handy approach involves creating a quick reference list, like the following:

- Measure the weight of a standard sheet using calibrated scales.

- Calculate the surface area of that sheet with accurate dimensions.

- Divide the weight by the surface area to obtain the roof sheet unit weight.

This method ensures consistency and precision, especially when comparing materials or planning for load-bearing requirements. By mastering the art of measurement and calculation, professionals can guarantee that every roof they craft is both resilient and beautifully crafted, with the right balance of strength and weight.

Methodology for Measuring Weight

Measuring and calculating the roof sheet unit weight might sound like a straightforward task, but it’s actually an art form that can turn into a delightful game of precision. Think of it as the culinary arts of construction—except instead of spices, you’re balancing weight with surface area to achieve perfection. The key is using accurate measurement tools: calibrated scales for weighing samples and precise rulers or laser measurements for surface dimensions.

Once you’ve gathered your data, a simple formula does the heavy lifting. Divide the weight of your sample sheet—measured in kilograms or pounds—by its surface area in square metres or square feet. This straightforward calculation yields the all-important roof sheet unit weight. For example, if a metal sheet weighs 10 kilograms and covers 2 square metres, its roof sheet unit weight is 5 kg/m². This number isn’t just a statistic; it’s the secret sauce that ensures your roof’s load-bearing prowess and structural harmony.

In practice, creating a quick reference list of typical weights for different roofing materials can save you from a lot of guesswork. Whether dealing with asphalt shingles, clay tiles, or innovative composite materials, knowing your roof sheet unit weight helps you plan for durability and compliance—because nothing says ‘professional’ like a roof that’s both resilient and optimally weighted.

Calculating the Unit Weight per Square Meter or Foot

Measuring and calculating the roof sheet unit weight might seem like a simple task, but it’s a vital step in ensuring a roof’s structural integrity. To get an accurate measurement, you need reliable tools—such as calibrated scales and precise surface measurement devices. By weighing a sample sheet and then measuring its surface area, you can determine the roof sheet unit weight with confidence. For instance, if a sheet weighs 10 kilograms and covers 2 square metres, its roof sheet unit weight is 5 kg/m². This calculation helps engineers and builders assess whether the roofing material will meet the load demands of the structure.

Understanding how to accurately determine the roof sheet unit weight is key for proper planning and compliance. A quick way to streamline this process is by creating a reference list of typical weights for different roofing materials—like asphalt shingles, clay tiles, or composite sheets—which can speed up decision-making on-site. Remember, precise measurement not only safeguards the longevity of your build but also maintains the safety standards essential for the durability of your construction.

Tools and Equipment Needed

Measuring the elusive essence of a roof sheet’s strength begins with the right tools—those humble yet critical instruments that transform raw data into vital insights. To accurately determine the roof sheet unit weight, a calibrated set of scales is your first ally. These scales must be precise, capable of capturing the subtle differences in weight that can dramatically influence a structure’s resilience. Alongside, a surface measurement device—be it a tape measure or laser scanner—helps delineate the exact area covered by the sample sheet, ensuring no detail is overlooked.

For simplicity and efficiency, many professionals turn to a straightforward approach: a sample weighing and surface measurement. This process can be streamlined with a basic yet reliable

- digital scale

- measuring tape

- calculator

. With these tools in hand, you can weigh the sample sheet, record the surface area, and swiftly compute the roof sheet unit weight. This meticulous attention to detail ensures that every calculation reflects the true load-bearing capacity, safeguarding both the longevity and integrity of your construction.

Factors Affecting the Unit Weight of Roof Sheets

Material Composition and Density

Understanding the factors that influence the roof sheet unit weight unveils a fascinating interplay between material composition and density. At its core, the unit weight hinges on the inherent properties of the materials used—metal, asphalt, clay, or plastic—each imparting distinct characteristics to the final product. For instance, a thicker metal sheet with higher alloy content naturally increases the roof sheet unit weight, enhancing durability but also adding to the overall load on the structure.

Material density plays an equally pivotal role, shaping the weight at a microscopic level. Heavier materials typically mean denser compositions, which can influence not only structural integrity but also installation procedures. Sometimes, manufacturers opt for lightweight composites or foam-filled panels to balance strength with manageability.

When considering the impact of these factors, it’s insightful to note that the choice of roofing material indirectly dictates the roof sheet unit weight—an essential consideration for architects and builders. Material selection, therefore, becomes a balancing act; heavier sheets offer longevity, while lighter options provide ease of handling and reduced structural strain.

Thickness of the Sheets

Ever wondered why some roof sheets feel like a feather and others like a small elephant? The secret lies in their thickness! Thicker roof sheets typically have a higher roof sheet unit weight, which means they add more heft to your roof structure. This isn’t just about bulk; it impacts everything from durability to how your building handles wind loads. And let’s not forget, increased thickness often correlates with enhanced insulation and longevity.

But here’s the kicker—thickness isn’t a one-size-fits-all deal. Manufacturers often adjust sheet thickness based on specific project requirements, balancing weight against ease of installation. For instance, a thicker metal roof might weigh more but significantly boosts durability. Conversely, thinner sheets reduce overall weight, making them perfect for renovations or lighter structures. Sometimes, selecting the right thickness involves considering factors such as:

- Structural load capacity

- Climate conditions

- Design aesthetic

Ultimately, the thickness of the roof sheet plays a pivotal role in determining the overall roof sheet unit weight, guiding architects and builders towards choices that strike the perfect balance between strength and manageability. Who knew that a simple millimetre difference could make such a hefty impact?

Manufacturing Processes

The manufacturing process significantly impacts the roof sheet unit weight, influencing both strength and ease of installation. Variations in production techniques, such as stamping, rolling, or extrusion, alter the density and overall mass of the sheets. For example, thicker steel sheets produced through advanced rolling methods tend to have a higher roof sheet unit weight, contributing to durability but also adding to the structural load.

Material composition plays a crucial role as well. Different alloys or additives can change the density, directly affecting the unit weight. Manufacturers often select specific formulations to meet project needs—balancing weight, corrosion resistance, and cost. Additionally, the process parameters, including temperature and pressure, can influence the final weight of the roofing material.

In some cases, the inclusion of core materials like foam or insulation layers modifies the overall unit weight. While these additions can reduce the weight of the outer shell, they also impact the roof sheet unit weight, especially in composite panels. Ultimately, understanding these manufacturing factors helps architects and builders choose the right roofing solution for optimal performance and load management.

Environmental Conditions and Age

Environmental conditions and age wield a subtle yet profound influence over the roof sheet unit weight. Exposure to elements such as moisture, UV radiation, and temperature fluctuations can gradually alter the material’s properties. Over time, some roofing materials may expand, contract, or even degrade, leading to changes in their overall weight. For instance, metal roof sheets subjected to corrosion or rust can experience a loss in mass, impacting the unit weight unpredictably.

Age is particularly significant as it correlates with wear and tear, often resulting in a reduction of the roof sheet unit weight. Conversely, the accumulation of debris, dirt, or even biological growth like moss can add to the weight, especially in older installations. Such variations can affect structural load calculations and long-term durability.

To better understand these influences, consider the following factors:

- Environmental wear and tear, including moisture ingress and chemical exposure

- Accumulation of debris or biological growth over time

- Material degradation, such as corrosion in metal roofing sheets

- Age-related structural fatigue affecting the density and weight

Why Roof Sheet Unit Weight Matters in Construction

Structural Load Considerations

Understanding the significance of roof sheet unit weight goes beyond mere numbers; it’s a cornerstone of structural safety in construction. A heavier roof sheet unit weight can influence the overall load on a building’s framework, potentially altering design choices to prevent long-term issues like sagging or collapse. Conversely, lighter materials might offer ease of installation but demand precise engineering to ensure durability.

In fact, selecting the right roof sheet unit weight involves balancing factors such as material strength, environmental conditions, and longevity. For example, metal roofing sheets with a higher unit weight may provide superior insulation and resistance, but they also add to the load that the supporting structure must bear.

When considering structural load considerations, it’s essential to evaluate the cumulative weight of all roofing components. Here’s a quick overview of what influences the roof sheet unit weight:

- Material composition and density

- Thickness of the sheets

- Manufacturing processes

Ignoring these details can lead to serious consequences—so understanding why roof sheet unit weight matters is fundamental for any construction project!

Wind Resistance and Durability

The weight of a roof sheet, often underestimated, wields a profound influence on a building’s resilience against relentless wind forces and its capacity to withstand the test of time. When gusts surge with ferocity, a heavier roof sheet unit weight can act as a stabilising anchor, resisting uplift and reducing the risk of catastrophic failure. Conversely, lightweight sheets, while easier to install, may require meticulous engineering to prevent vulnerabilities arising from high wind pressures.

In high-wind environments, understanding the importance of roof sheet unit weight becomes paramount. The added mass creates a counterforce that diminishes the likelihood of wind-driven uplift, anchoring the structure firmly to the earth. Yet, the trade-off manifests in increased load on supporting frameworks, demanding careful consideration during design phases. For durability, the right balance ensures that the roof endures environmental assaults—be it harsh weather or prolonged exposure—without compromising safety or longevity.

- Wind resistance

- Structural stability

- Long-term durability

Choosing materials with appropriate roof sheet unit weight is more than a matter of compliance; it is a strategic decision that influences the entire lifespan of a building. The nuanced interplay between weight, wind resilience, and durability underscores the critical importance of precise calculations and informed material selection in construction projects.

Transport and Handling

In the intricate dance of construction logistics, the weight of each roof sheet becomes a silent yet potent factor that determines the ease and safety of transport and handling. A heavy roof sheet unit weight can transform a seemingly straightforward installation into a logistical challenge, demanding specialised equipment and meticulous planning. Conversely, lighter sheets often glide more effortlessly through narrow doorways and tight corners, reducing labour time and safety risks.

Understanding the precise roof sheet unit weight is crucial for selecting the right handling techniques. For example, materials with a higher weight might necessitate cranes or forklifts, while lighter alternatives can often be manoeuvred manually or with simpler machinery. Overlooking this aspect risks not only delays but potential damage to the sheets or injury to workers, which can be costly and dangerous. Careful calculation and awareness of the roof sheet unit weight ensure that transportation remains smooth, secure, and efficient—an essential consideration in the grand architecture of building projects.

Installation and Support Requirements

In the grand symphony of construction, the roof sheet unit weight plays a surprisingly pivotal role—yet it often goes unnoticed. Ignoring this seemingly small detail can turn a straightforward installation into a logistical nightmare. Heavy roof sheets demand stronger support structures and more robust handling equipment, which can escalate costs and extend timelines. Conversely, lighter sheets lend themselves to quicker, safer installation, reducing the strain on both workers and building frameworks.

Understanding the roof sheet unit weight isn’t just about knowing numbers; it’s about ensuring structural integrity and safety. For instance, materials with a higher weight might require additional support beams, while lighter options can be manoeuvred with minimal fuss. This knowledge helps project managers decide whether to deploy cranes, forklifts, or manual labour, ultimately influencing the entire construction strategy.

- Structural load considerations

- Wind resistance and durability

All these factors hinge on accurately assessing the roof sheet unit weight, making it a cornerstone of effective support requirement planning. Without this insight, even the most beautifully designed roof can become a liability rather than an asset—highlighting why this metric is more than just a number in the world of roofing. It’s the unsung hero of seamless, safe, and efficient building projects!

Standards and Regulations for Roof Sheet Weight

International Building Codes

In the realm of construction, adhering to international standards and regulations for roof sheet unit weight is paramount to crafting structures that stand the test of time. These codes serve as guiding stars, ensuring that each sheet’s weight aligns with safety, durability, and performance benchmarks. When engineers and architects select roofing materials, they must navigate a labyrinth of specifications, from the uniformity of material composition to the environmental influences that subtly alter weight over decades.

International building codes, such as those from the International Code Council (ICC), set rigorous mandates that encompass the permissible range of roof sheet unit weights. These standards not only regulate safety but also optimise the structural integrity of entire edifices. For instance, some codes specify maximum allowable weights to prevent undue stress on supporting frameworks, while others specify minimum weights to ensure resilience against weather extremes.

To harmonise these diverse criteria, professionals often rely on detailed tables and charts, which delineate acceptable ranges for various materials and environmental conditions. Adhering to these standards transforms the roof sheet unit weight from mere numbers into a vital compass guiding safe and efficient construction—an invisible yet indelible mark of quality and compliance. As global regulations evolve, the importance of understanding and respecting these standards remains the cornerstone of responsible building practice.

Local and National Standards

Standards and regulations governing roof sheet unit weight form the backbone of safe and sustainable construction practices. These rules, whether set by local authorities or national bodies, serve as essential benchmarks that ensure roofing materials meet durability and safety criteria. In many regions, adherence to these standards is not merely recommended but legally mandated, reflecting a collective commitment to structural integrity.

For instance, national codes often specify permissible ranges for roof sheet unit weight, balancing the need for strength against material efficiency. They also consider environmental factors—such as wind loads and climate extremes—that influence the ideal weight of roofing sheets. To navigate this regulatory landscape, professionals frequently consult detailed tables and charts, which provide clear guidance on acceptable weight ranges for various materials and installation contexts.

Ultimately, understanding and complying with these standards ensures that the roof sheet unit weight aligns with broader safety and performance goals. It’s a subtle dance of precision and foresight, where each kilogram counts in the pursuit of long-lasting, resilient structures. As regulations continue to evolve, so too does the importance of a meticulous approach to selecting roofing materials—grounded firmly in respect for these vital standards and regulations for roof sheet weight.

Impact on Insurance and Safety Compliance

In the intricate tapestry of modern construction, the impact of standards and regulations on roof sheet unit weight extends far beyond mere compliance. These benchmarks serve as an invisible yet unwavering compass, guiding engineers and architects through the labyrinth of safety and insurance considerations. When a structure’s roof adheres to these prescribed weight ranges, it not only satisfies legal mandates but also fortifies itself against unforeseen liabilities that could jeopardise safety or inflate insurance premiums.

Regulatory frameworks often delineate precise parameters for roof sheet unit weight, considering environmental factors such as wind uplift, snow loads, and extreme weather conditions. Non-compliance can lead to catastrophic consequences—ranging from structural failure to increased risk of insurance claims. To facilitate adherence, detailed charts and data tables are typically employed, providing clarity on acceptable weight ranges for different materials and installation scenarios.

In essence, the meticulous attention to roof sheet unit weight within regulatory standards acts as a safeguard—ensuring that the structural integrity remains uncompromised and that safety compliance is woven into the very fabric of building design. As these standards evolve, the importance of vigilant material selection and precise measurement becomes ever more critical, underpinning both the resilience of the structure and its insurability in the long term.

- Ensuring optimal safety standards

- Reducing insurance risk and premiums

- Meeting legal and regulatory compliance

Comparing Roof Sheet Weights for Material Selection

Pros and Cons of Heavy vs Light Roofing Sheets

The choice between heavy and light roofing sheets often feels like a crossroads in the grand voyage of construction — each path offering distinct treasures and challenges. Heavy roofing sheets, such as traditional clay tiles or dense metal options, boast remarkable durability and superior wind resistance, making them stalwart guardians against the fiercest storms. However, their substantial weight increases the roof sheet unit weight, demanding robust support structures that can handle the load.

Conversely, lighter roofing sheets, including PVC or composite materials, often reduce the overall weight of the roof assembly, easing transportation and installation. They are particularly advantageous in regions where structural reinforcement is limited or where rapid deployment is essential. Yet, their lower weight sometimes correlates with decreased wind resistance and longevity, which may influence long-term safety and maintenance costs.

Balancing these aspects hinges on understanding the implications of roof sheet unit weight — a pivotal factor that shapes the entire lifecycle of the roof, from initial design to enduring resilience.

Cost Implications

When selecting the ideal roofing material, understanding the impact of roof sheet unit weight on costs can be transformative. Heavier materials like clay tiles or dense metal sheets tend to have a higher roof sheet unit weight, which directly influences both material expenses and structural reinforcement requirements. These robust options often carry a premium price, not only because of their durability but also due to the additional support structures they demand. Conversely, lighter options such as PVC or composite roofing sheets usually translate into lower initial costs, thanks to easier transportation and quicker installation processes.

To put it into perspective, the difference in roof sheet unit weight can be significant — sometimes ranging from 3 to over 20 kilograms per square metre. This variance affects the entire project budget, including labour, transport, and even long-term maintenance. When choosing a roofing material, it’s essential to weigh these factors against the longevity and performance expectations of the roof. After all, a lighter roof may save money upfront but could incur higher costs in repairs or replacements over time due to reduced wind resistance. Ultimately, understanding the nuances of roof sheet unit weight ensures more informed, cost-effective decisions tailored to your unique construction needs.

Long-term Performance and Maintenance

Choosing the right roofing material isn’t just about aesthetics; long-term performance hinges on roof sheet unit weight. Lighter materials like PVC and composite sheets tend to have a lower roof sheet unit weight, which can translate into easier installation and reduced structural support. However, these lighter options may face challenges such as lower wind resistance and increased susceptibility to damage over time.

Conversely, heavier materials such as clay tiles or dense metal sheets offer superior durability and resilience. Their increased roof sheet unit weight often enhances wind resistance and overall longevity. But this comes with higher costs in transport, handling, and structural reinforcement. For some projects, this trade-off means prioritising resilience over initial savings.

- Evaluate environmental exposure—heavier sheets may better withstand harsh weather conditions.

- Consider maintenance needs—lighter materials might require more frequent repairs or replacements.

- Assess structural capacity—ensure the building can support the weight of heavier roofing sheets without compromise.

Understanding these nuances in roof sheet unit weight helps optimise not just the initial investment but also the long-term durability and safety of the roof. It’s a critical factor that influences both construction quality and ongoing maintenance costs, shaping the overall success of your roofing project.

Practical Tips for Choosing the Right Roof Sheet Weight

Assessing Structural Capacity

Choosing the right roof sheet unit weight is akin to finding the perfect pair of shoes — it must balance comfort, durability, and style. An overly heavy sheet might strain your roof’s structural integrity, while a featherlight alternative could leave your building vulnerable to the whims of the weather. Interestingly, the roof sheet unit weight influences not only the overall load but also how well the roof resists wind and other environmental assaults. It’s a delicate dance that demands careful assessment and a touch of engineering intuition.

To navigate these choppy waters, consider these practical tips: First, evaluate the **structural capacity** of your building—knowing its load-bearing limits is paramount. Second, factor in environmental conditions—harsh climates demand more robust options, while milder zones allow for lighter sheets. Lastly, consult local building regulations and standards, as they often specify minimum or maximum roof sheet unit weights to ensure safety and compliance. Remember, a well-chosen roof sheet weight isn’t just about the material itself; it’s about harmonising that weight with your building’s unique needs and resilience. Sometimes, a lighter sheet with high durability can outperform a heavier one in the long run, provided it’s properly supported and installed—so weigh your options wisely!

Climate and Weather Considerations

When selecting the ideal roof sheet unit weight, understanding the influence of climate and weather conditions is crucial. In regions prone to heavy winds, snow, or intense rainfall, opting for a higher unit weight can significantly bolster your roof’s resilience. Conversely, milder climates often permit lighter sheets that reduce overall structural load without compromising durability.

Consider these practical insights:

- Heavy, storm-resistant materials often have a higher roof sheet unit weight, providing better wind resistance and structural integrity.

- In contrast, lighter sheets may be advantageous in areas where seismic activity or snow load is minimal, easing installation and reducing support requirements.

Recognising how environmental factors impact the performance of roofing materials allows you to weigh the benefits of different roof sheet unit weights. Remember, the goal isn’t just to find the heaviest option but to balance weight with environmental demands. An optimally selected weight ensures longevity, safety, and compliance—transforming your roof from mere shelter into a resilient shield against nature’s unpredictability.

Design Aesthetics and Functionality

Choosing the right roof sheet unit weight is a delicate balance between aesthetics and functionality. It’s tempting to opt for lightweight sheets to ease installation, but durability and wind resistance shouldn’t be compromised—especially in areas prone to storms. The key is to consider how the weight of your roofing material complements your building’s overall design while providing the necessary protection against environmental challenges.

For structures where resilience is paramount, heavier roofing sheets offer superior wind resistance and longevity. Conversely, lighter sheets can be advantageous in seismic zones or regions with minimal snowfall, reducing support requirements and easing handling during installation. Recognising the significance of roof sheet unit weight in your project ensures your roof remains a steadfast shield over the years, blending beauty with resilience.

Budget and Cost-effectiveness

Choosing the optimal roof sheet unit weight is a dance of delicate balance—where cost-effectiveness meets structural integrity. When budgets are tight, it’s tempting to lean towards lighter roofing sheets; however, sacrificing durability can lead to costly repairs down the line. To navigate this terrain wisely, consider the long-term performance of your materials. Heavier roof sheets often offer superior wind resistance and longevity, providing a steadfast shield against nature’s fiercest assaults. Conversely, in seismic zones or areas with minimal snowfall, lighter roof sheets can reduce the load on supporting structures, easing installation and lowering initial expenditure.

A practical approach involves evaluating your project’s environmental conditions and structural capacity. Here’s a quick guide:

- Assess environmental challenges—wind, snow, seismic activity.

- Calculate the structural load capacity of your building.

- Factor in installation and handling costs.

By understanding these elements, you ensure your roof sheet unit weight aligns seamlessly with both your budget and the demands of your locale, transforming a simple choice into a strategic asset.

0 Comments